King Boat Works: 140 hours for a boat that will last a decade.

The first time Graeme King saw “a real live 8”—an eight-oared rowing shell, or boat—was in Adelaide, South Australia, when he was fourteen years old. He’d been fascinated with them as a small child ever since he saw them in newsreel recaps of shell races. “I was pretty impressed when I saw it,” he says. “And I just told myself, ‘I’d like to make one of those one day.’”

He got his chance a few years later, when he picked up some World War II surplus plywood for twenty-five cents a sheet and built one from scratch with just the hand tools he had available. “I guessed pretty wrong at the internal structure,” he says, laughing softly. “But I learned a lot.”

Others began to ask him to build shells—one of which, a “single” (for one rower), won its owner a national championship. After that King joined the Harvard rowing program in America, then returned to Australia to start a business building shells—instead of going into railroad engineering as planned. The decision was made for him when he sat down to take his engineering exams and fifty more students took their seats. “I realized no one was building shells, but there were a lot of engineers,” he says.

When he moved back to the United States in 1980, King Boatworks took up its current home in Vermont. For much of his career, he has made shells out of wood instead of carbon fiber, thanks to a weapons research scientist who told him early on: “If you make them out of carbon fiber, you’ll make more money; if you make them out of wood, you’ll have more fun.”

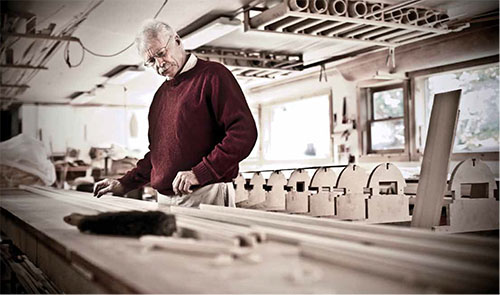

King says the art of building wooden shells is what makes them beautiful, while the science behind their construction is what makes them fast. After building the pieces for the framework, he assembles it on a jig, then gives it a coat of varnish. After that he shapes the framework so it can hold the plywood layers that make up the hull. The plywood is one sixteenth of an inch thick, and it’s stretched and shaped carefully over the form, then attached to the framework before the interior is varnished. Adding the other elements he’s constructed—seats, riggers, fittings—comes last. It takes 130 to 140 hours to complete a boat that’ll last for decades.

Much of his work with wooden shells these days is refurbishing. And he has expanded his work to include carbon fiber boats as well.

“People are confused when they first see one of these boats, unsure if it’s a piece of modern art or some lethal missile,” King says. Rowing shell design is ever-changing, he adds, and advanced design work is where he spends much of his time now. Not surprising, since he’s still an engineer at heart. An engineer who happens to love real live 8s.